Blog

Get troubleshooting tips, maintenance guides, and the latest in automation — all in one place. Updated monthly.

1/1

Tutorials

How to Troubleshoot Fanuc Alarm 8, 9, A

Getting FANUC Alarm 8, 9, or A? It's high current—here's the fix.

Tutorials

Reset Ownership Allen Bradley Safety PLC

What to do when your safety PLC can’t take ownership of a safety device.

Checklists

Welding Machine Checklist

Learning Series

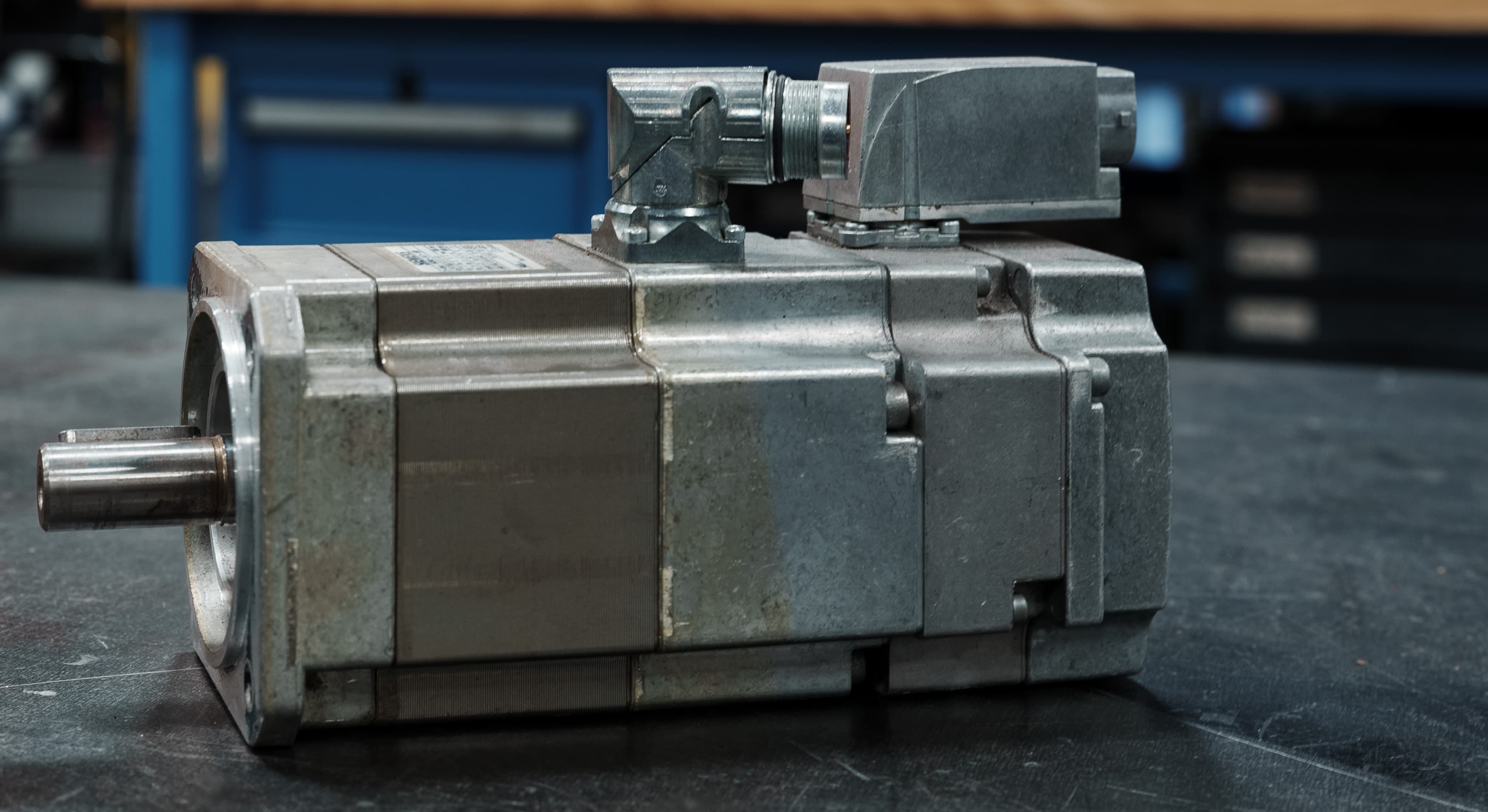

What is a Servo Motor

Go inside the housing. See the parts that matter. Understand how it works—and why it's critical to motion control.

Guides

AC Drive Overcurrent Prevention

Learning Series

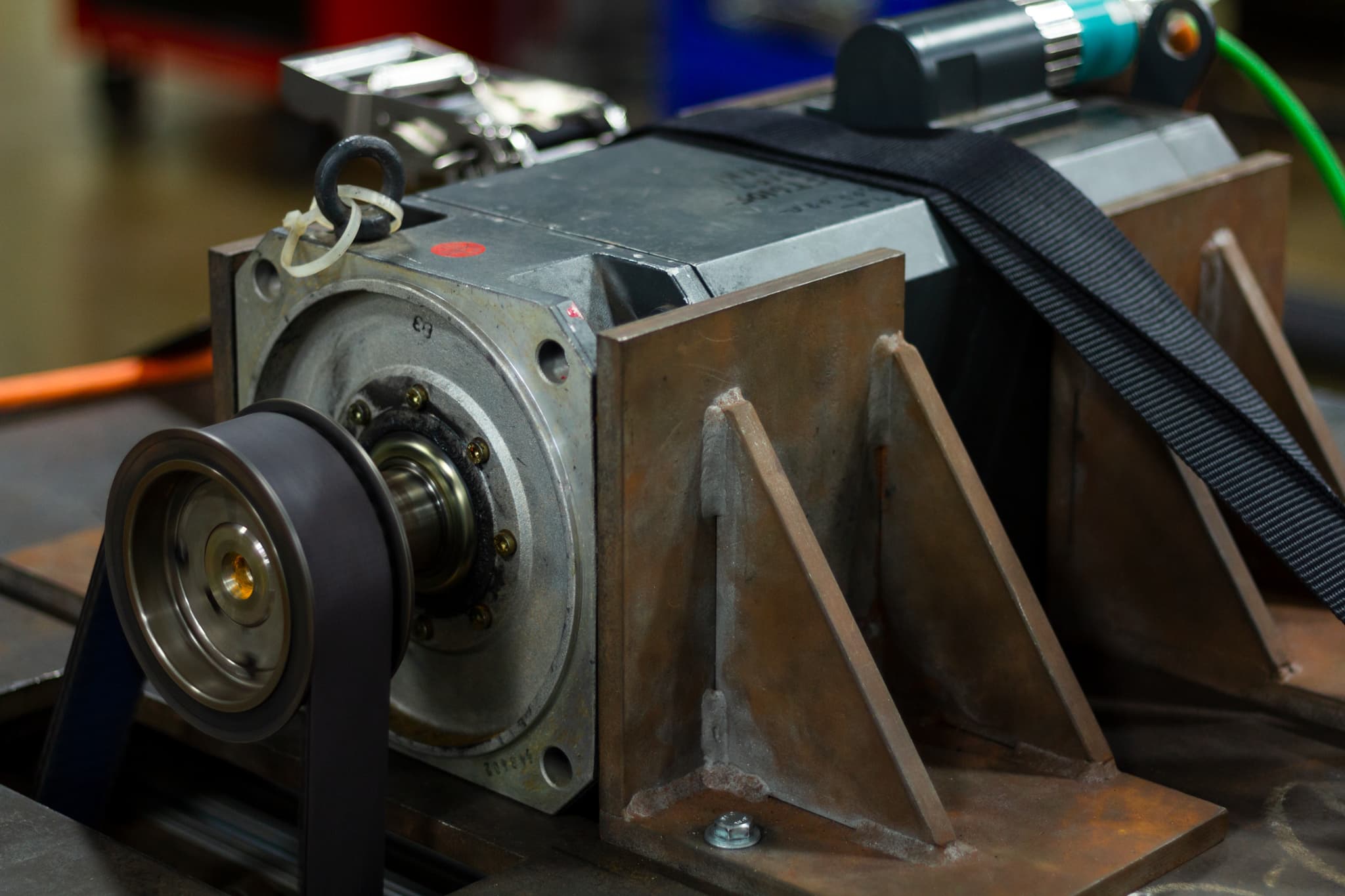

How Dynamometers Work

Checklists

Servomotor Maintenance Checklist

Learning Series

What is Stall Torque

The rotational force where motion stops. That’s stall torque—and it matters.

Learning Series

What is a Teach Pendant

Case Studies

Strategic Fix Eliminates Top 10 Failure at Stellantis

Forty-four KEBA Kemro K2-700 controllers were failing, disrupting Ram ProMaster production.

1/1