CNC Repair

Multi-axis Machining Centers, Horizontal and Vertical Mills, Lathes, and Grinders

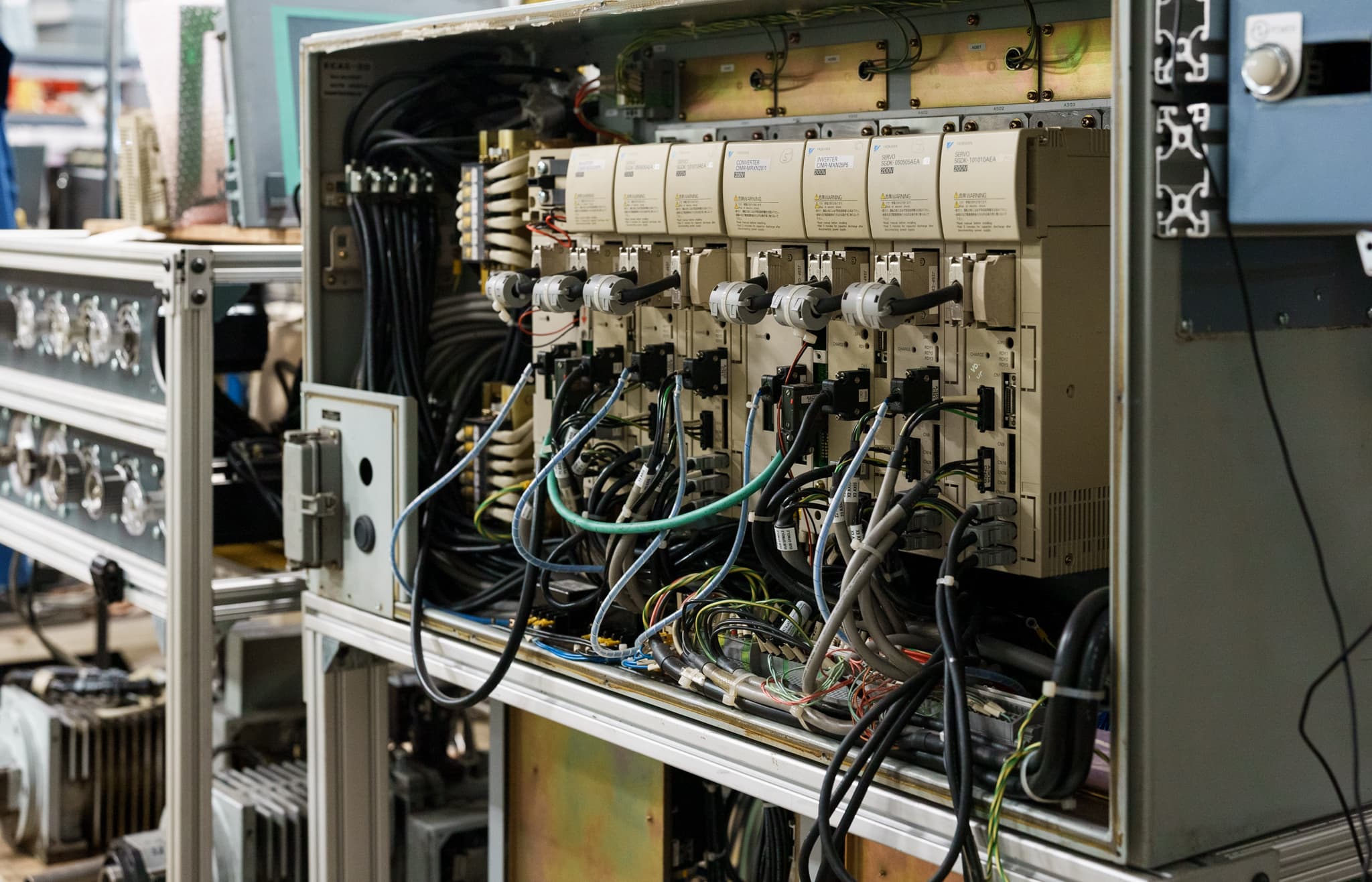

CNC Machine Repair

Subassembly

Repair single and dual-axis drives, 3-phase motors, operator panels, power supplies, and more.

Technology

ICR invests $355K—installs 3 dynamometers to test machine tools.

Zero fail initiative.

Spindle

Spindle motors accelerate rapidly, drawing 250% of the drive's rated amperage for 0.01 seconds.

Servo

Servo motors start at zero speed with 100% load and need 150% of the drive's rated amperage for 0.2 seconds to initiate movement.

Milling and Turning

CNC Controllers

Siemens, Fanuc, Mitsubishi, Rexroth Indramat, and OKUMA.

Authorized Service Center

Star CNC Machine Tool Corp.

10-axis ECAS-20 and 11-axis ECAS-32T Swiss lathes.

Full-service

24/7 CNC Support

Machine availability.