CNC Control Systems and Machines

CNC control systems are powerful devices that create consistent work in your machine shop, but the machines these systems power are fragile beasts that need attention. To properly care for your machine, it’s important to use a maintenance program that will help keep your CNC machine in good condition. Every CNC machine is under stress every day, and proper maintenance will prevent problems with your device in the future. The following are seven reasons why it’s a good idea to add a preventive maintenance plan to your vital equipment. Following the steps below and maintaining the machine while ensuring proper parts usage and using knowledgeable service technicians provide reliability.

7 reasons to add preventive maintenance

Regular Cleanings

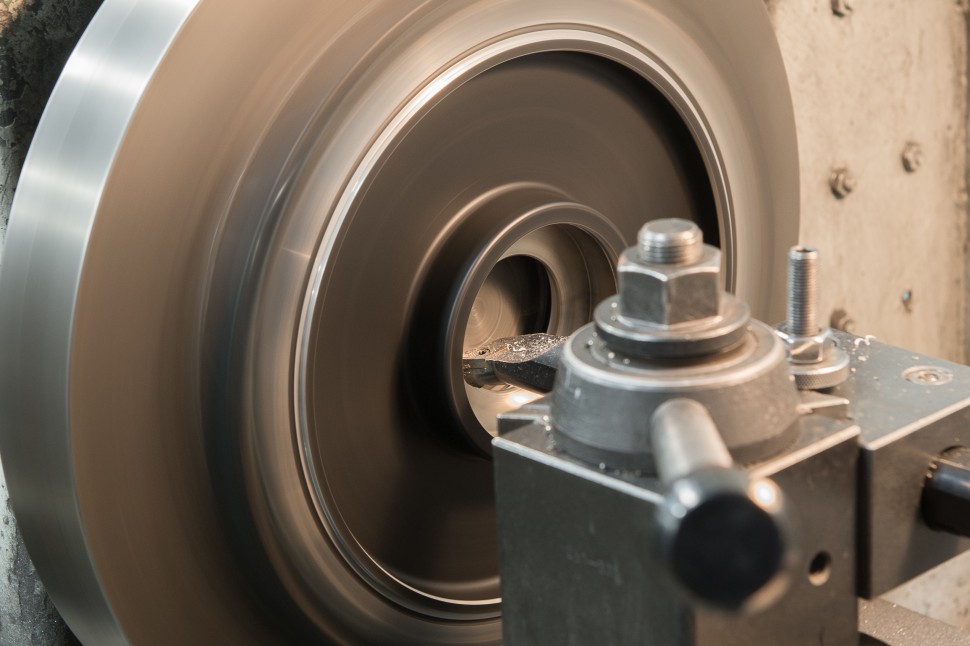

Regular cleaning of all the components within your machine will help you keep the machine in good condition. The heads that grind away material get dirty easily, and the interior of the machine collects debris all day. The debris will cause problems inside the machine, and you must clean the machine at the end of the week to start well on Monday morning.

Replace Vital Parts

Essential components of the machine must often be replaced. The heads, rotor arms and motor have small parts that should be replaced when they wear down, and you must keep extra parts in the facility for simple repairs. You may purchase these parts in bulk, or the rotor heads may come in different styles.

Protect The Power Supply

You must plug your CNC machine into a proper power outlet, or you must use a surge protector. Surge protection prevents damage to the wiring in the machine, and you must check the cable for damage as you work. Any damage to the power cord could cause a short in the system, and you must replace the power cord before something happens to your CNC machine.

Protect The Outer Casing

The casing on the CNC machine must be kept clean and free of marks at all times. Caring for the exterior of the unit helps you maintain the integrity of the interior, and you must prevent scratches and dents from overtaking the machine. Your CNC machine loses its value when you do not care for it properly, and you cannot sell a used unit that is dirty or damaged.

Responsible Machine Operation

You must let your CNC machine rest between projects. Running the machine every day wears it down faster, and you must plan breaks during the work day when the machine is not in use. You may leave the power on at all times, but you cannot run the machine continuously while expecting it to last forever. Wise use of your CNC machine will save money and repairs you cannot afford.

Immediate Repairs

Any problems with your CNC machine must be repaired immediately. All repairs must be completed by a certified professional, and you should ask for an inspection of the unit when the repairman arrives. A repairman can see what is wrong with your unit immediately, and the repairs can be completed almost immediately. Any repairs that are left for too long will cause extra damage to your device that could cause it to break down completely.

Longevity

Your preventative maintenance plan will help your machine run for many extra years past the life of the warranty, and you will have a better chance of selling the machine when you want to replace it. Wearing down your CNC machine with years of abuse will leave you with a machine that is worthless in the end. Proper maintenance helps you keep up a machine that will serve your business now and in the future.