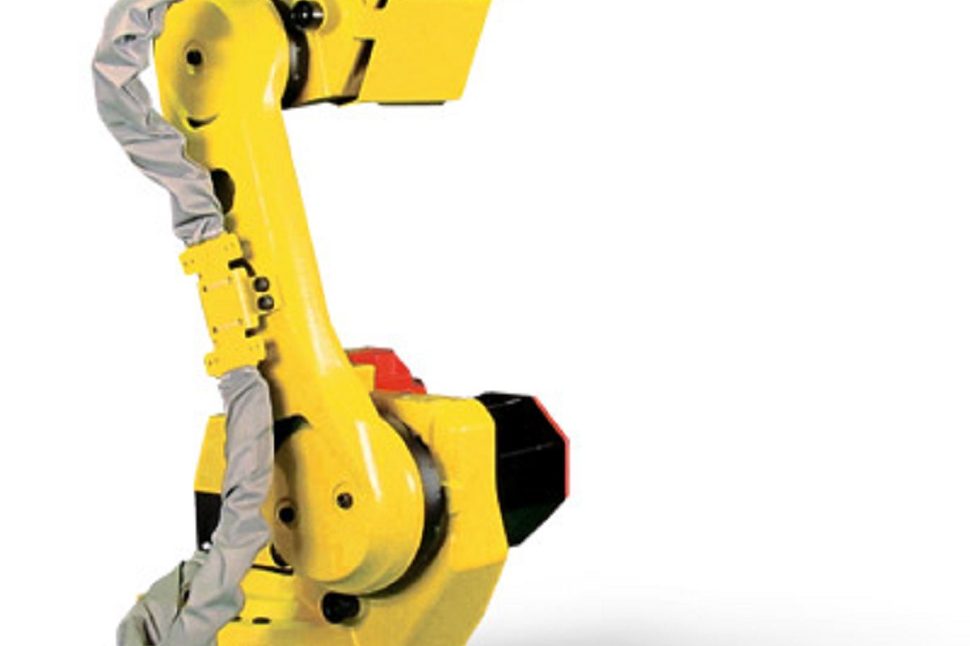

Testing repaired Fanuc Robotic parts with the R-30iB Controller

ICR’s electronic technicians utilize Fanuc’s R-30iB controller paired with an M-10iA robot. Applications like assembly, packaging, material removal, part transfer and dispensing utilize the high-performance of Fanuc’s robot and controller pair. Fanuc Robotic parts repaired by ICR undergo an extensive process that fixes defects, and replaces aged or defective components. After repair, technicians run each part through a substantial testing procedure, which also includes the ability to test all 6 axis. Our testing procedures provides customers with a guarantee of reliability and longevity, which is backed by a in-service warranty.

Fanuc Robotic Parts Supported by ICR

Supported Parts

- Fanuc A05B-2255-C102 #EMH Teach Pendant

- Fanuc A16B-2203-0910/07A Power Supply

- Fanuc A16B-3200-0780/02A Main CPU

- Fanuc A06B-6400-H003 C Servo Amplifier

- Fanuc A05B-2600-C001 Backplane

- Fanuc A05B-2601-C410 E-stop Unit

An improvement on Fanuc’s Series 30iB Robotic Controller

Fanuc’s R-30iB controller features high-performance hardware including advanced in-network communications integrated iRVision, and motion control functions. Another exciting feature, exclusive to Fanuc, is the new easy operating touch screen iPendant with 4D graphics. Fanuc’s iPendant displays process information, while displaying the current process path on the iPendant screen. This set-up provides users with an easier setup and more feature-rich troubleshooting experience. This much more compact controller is based on Fanuc’s Series 30iB Robotic Controllers. The small size provides customers with a significant amount of space savings while also providing an energy efficient operation with less overall power consumption.