How ICR provides motor refurbishment

Process-driven refurbishment

- Evaluation of industrial motors on-site for a formal quoting process

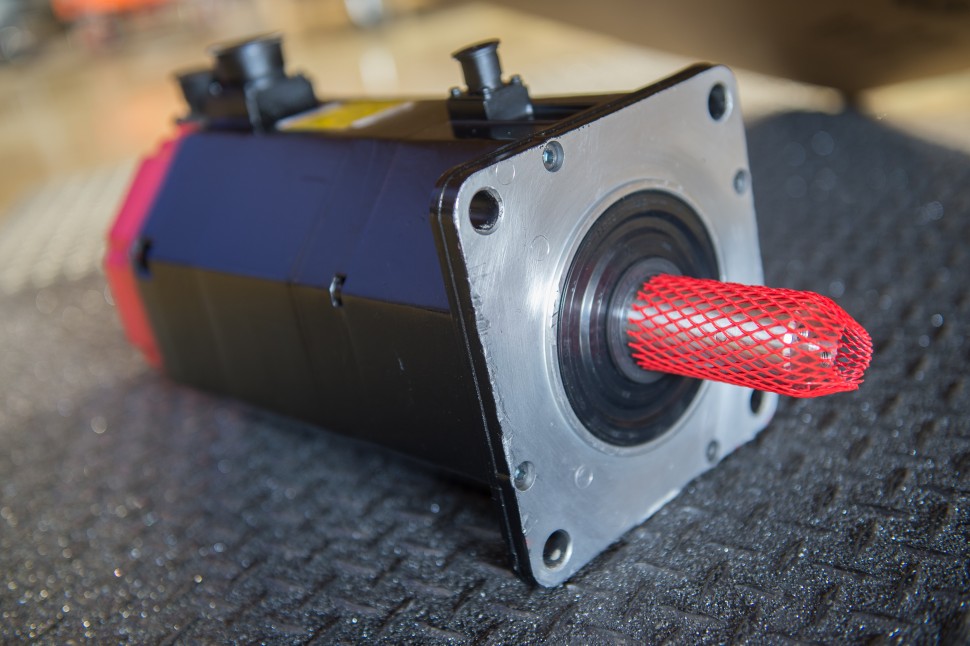

- Disassembly of industrial motors

- Cleaning and repainting

- Inspection of motor components

- Replacement of damaged parts

- Rebuild or rewinding of the motor

- Testing process using our proprietary in-house engineered equipment

Determine the root-cause

ICR separates itself from the competition by offering both repair and refurbishment services for industrial motors. From basic repair to larger, more complex issues, we are confident in our abilities to provide solutions for all situations. Our repair methods include steps derived from a root-cause analysis, which is a process that adequately analyzes the failure of a difficult or recurring theme. This approach is considered a best practice among industry leaders and one ICR has effectively honed over time.

30% to 50% savings vs. new equipment

When equipment is beyond repair and requires a full refurbishment, ICR employs a specialized process to reset specifications back to their original OEM settings or higher. The refurbishment process has been proven to provide savings over the cost of purchasing either surplus or new equipment. Utilizing an in-house machining and fabrication shop, ICR technicians manufacture the custom parts that are needed to bring equipment up to requirements. Since ICR strives to excel beyond the base minimum, we also manufacturer brakes in-house and never send a motor out without a refreshed brake.

Request Industrial Motor Repair

Contact us below and an ICR customer service representative will respond as soon as possible to offer assistance. Please provide the type of motor, manufacturer and part number if possible. Make sure to provide as much detailed information about your motor and we will be in touch soon.

If the manufacturer of your motor is not listed, please inquire and we will determine if we have a solution

[contact-form-7 id=”2643″ title=”Industrial Motor”]