How ICR Repairs and Tests Siemens Servo Motors

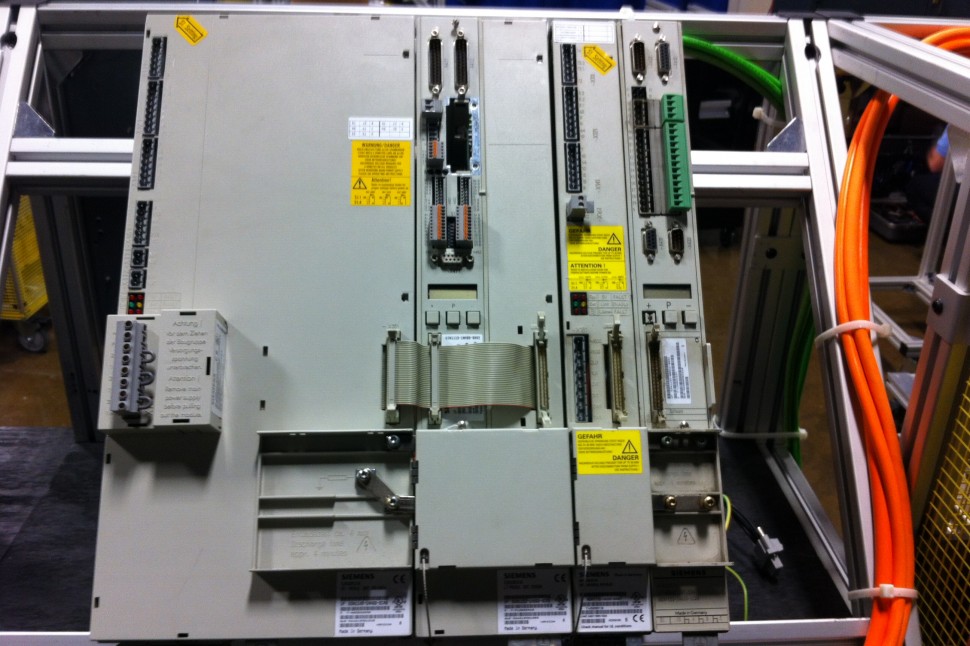

ICR’s repair process begins with a complete unit cleaning by a technician. Preventive maintenance is performed to update all optoisolators and capacitors on each unit. Then the unit will be tested with flywheel motors. An example of this can be seen here, as ICR’s engineering team built a test stand designed primarily to test repaired Siemens Servo Motors, and replicate real life applications. Communication to the test stand is sent via the Siemens Simocom U control software allowing for testing in both manual and automatic mode. Dependent upon the servo motor series a dyno test to wrap up the repair process may occur to ensure reliablity and longevity under operation.

Supported Components

- Siemens 1FT5 Series Servo Motors

- Siemens 1FT6 Series Servo Motors

- Siemens 1FK6 Series Servo Motors

- Siemens 1FK7 Series Servo Motors

- Siemens 1PH6 Series Servo Motors

- Siemens 1PH7 Series Servo Motors

Siemens SimoDrive 611

An attractive option within the manufacturing and processing industry many plants feature the Siemens SIMODRIVE 611 converter systems. The SIMODRIVE suite of products can provide assistance for many machining applications when AC converters with low voltage requirements are needed. The SIMODRIVE 611 converter system from Siemens allows individual drive assemblies to be combined thus enabling fast and flexible synchronization of the drive performance and some machine axes, according to Siemens. They mention further that the system is both a modular transistor pulse-controlled converter, which makes it flexible enough to be adapted to any area of application.