The Design and Fabrication of Custom Automation Systems

Working Together to Drive Innovation

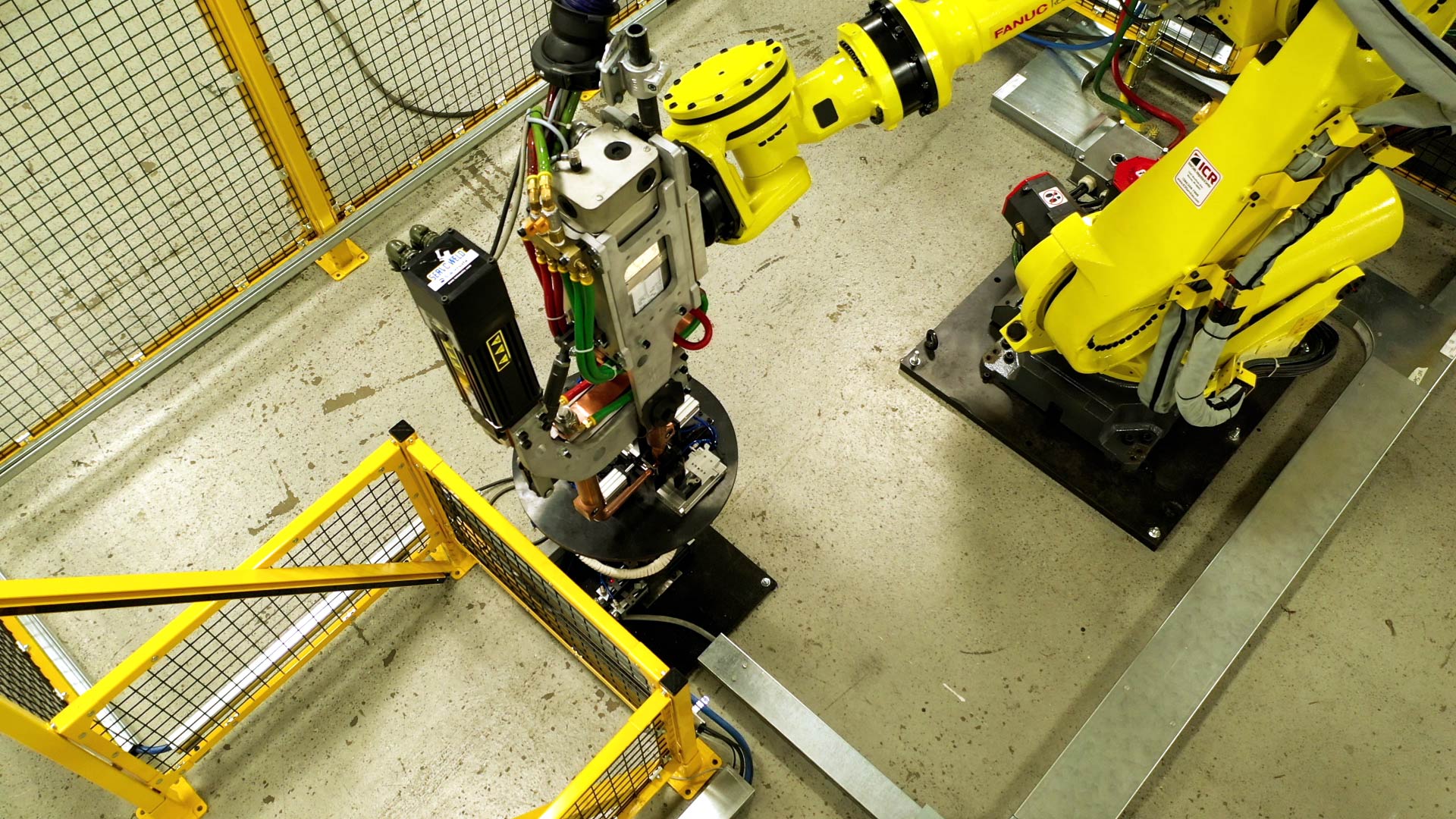

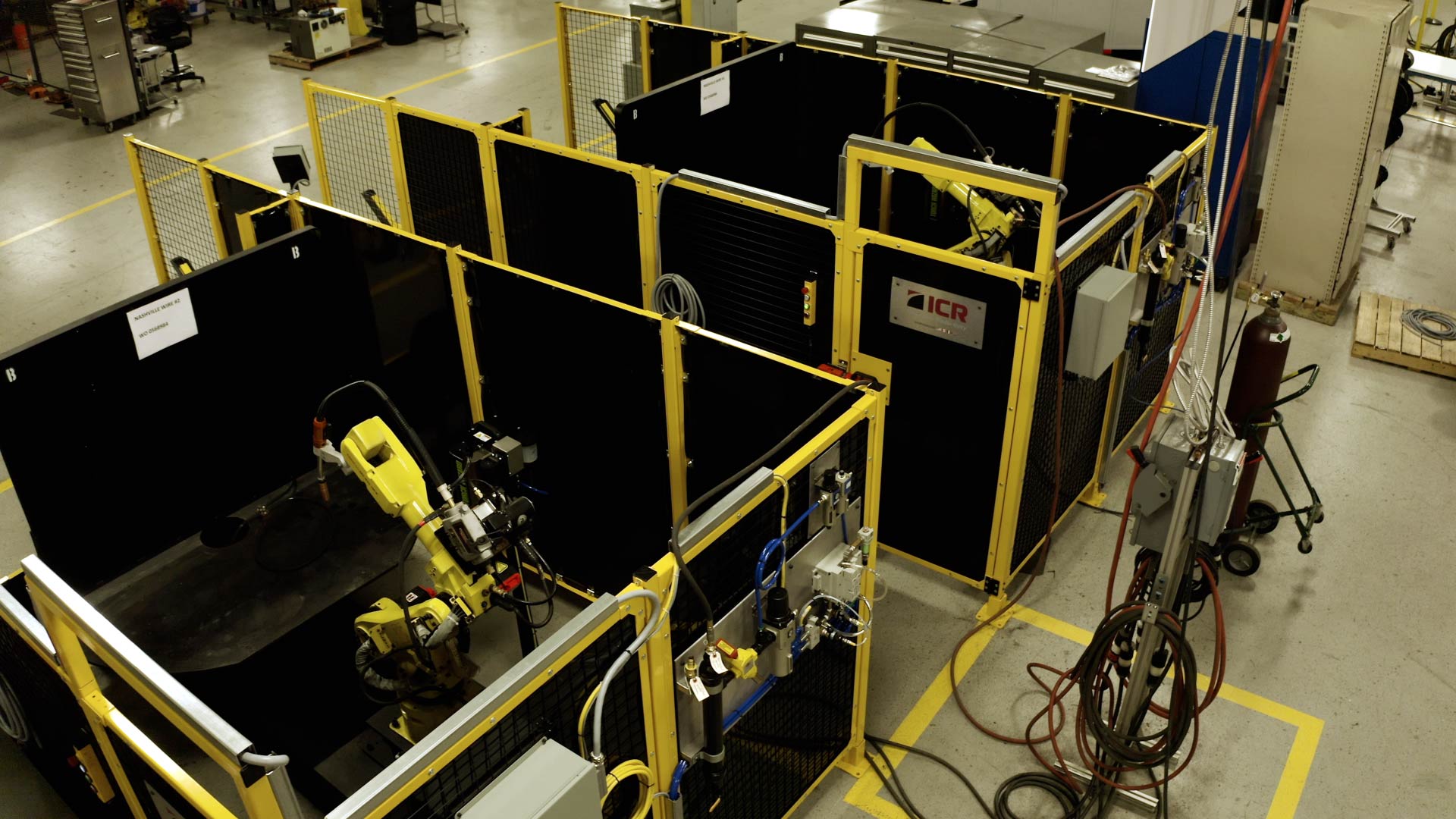

ICR Services designs, builds, and integrates custom industrial automation solutions for some of the world’s leading manufacturers.

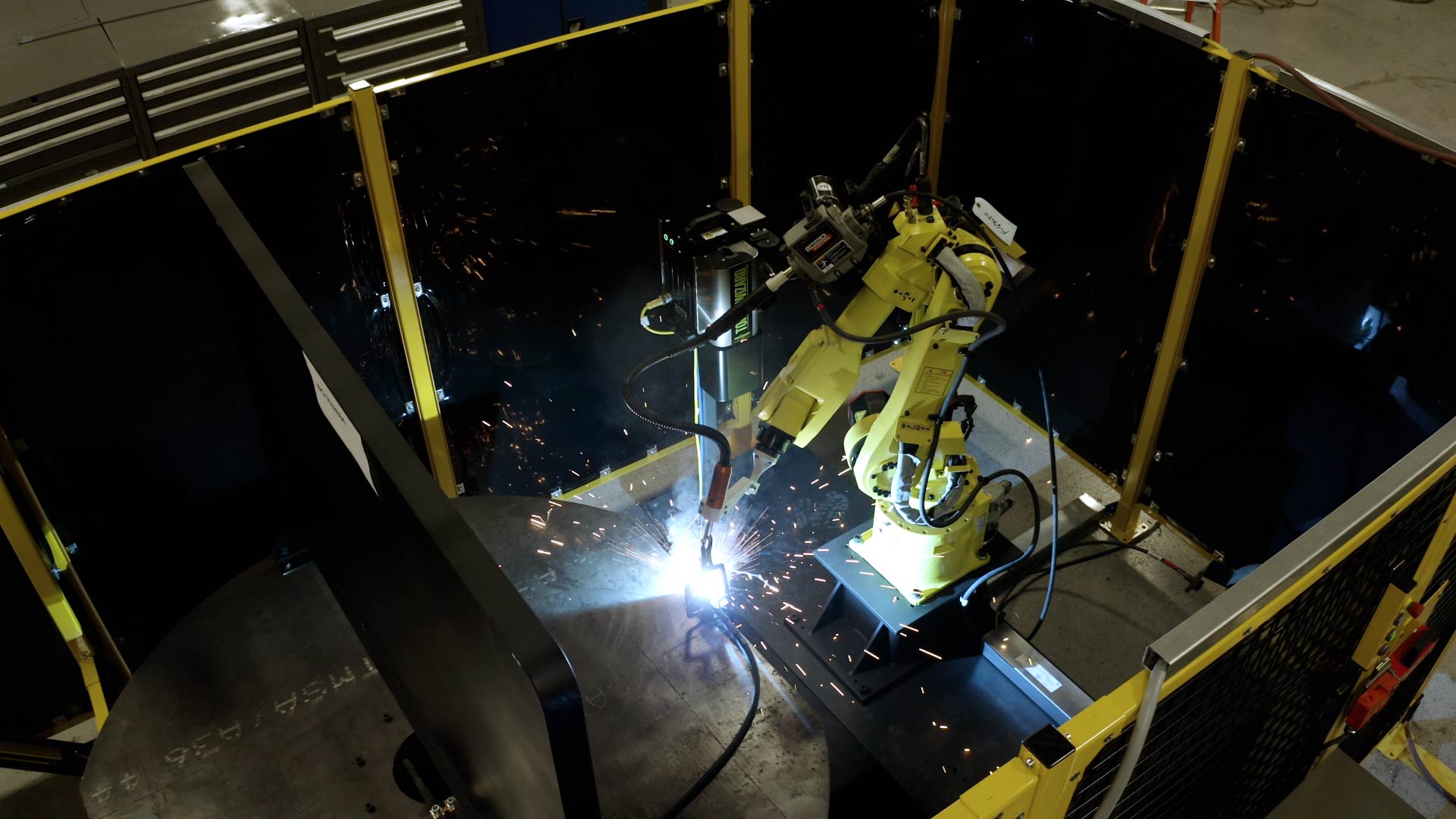

We’re a team comprised of engineers, machinists, and designers who work to bring an unknown integrated automated solution into existence. The cell meets demanding specs and solves previously unsolvable issues.

Certified Robot Systems Integrator and Distributor for the Following OEMs

Advanced manufacturing requirements keep innovation in the industrial automation space prospering and at the forefront of our robotic integration division. We work closely together with you and our fully staffed integration team to clearly define a Proposal Summary and Project Scope of Work best suited to solve the unique challenges plaguing your production before even beginning the design stage.

Refurbished Robot vs. New Robot

We are well equipped to help you determine the right new or used robot needed for your specific application. Using Refurbished Robots has many small manufacturers – even big ones – saving thousands without sacrificing performance.

Learn How a Metal Stamping Facility Improved Quality and ProfitabilityBenefits of Manufacturing Automation with ICR Services

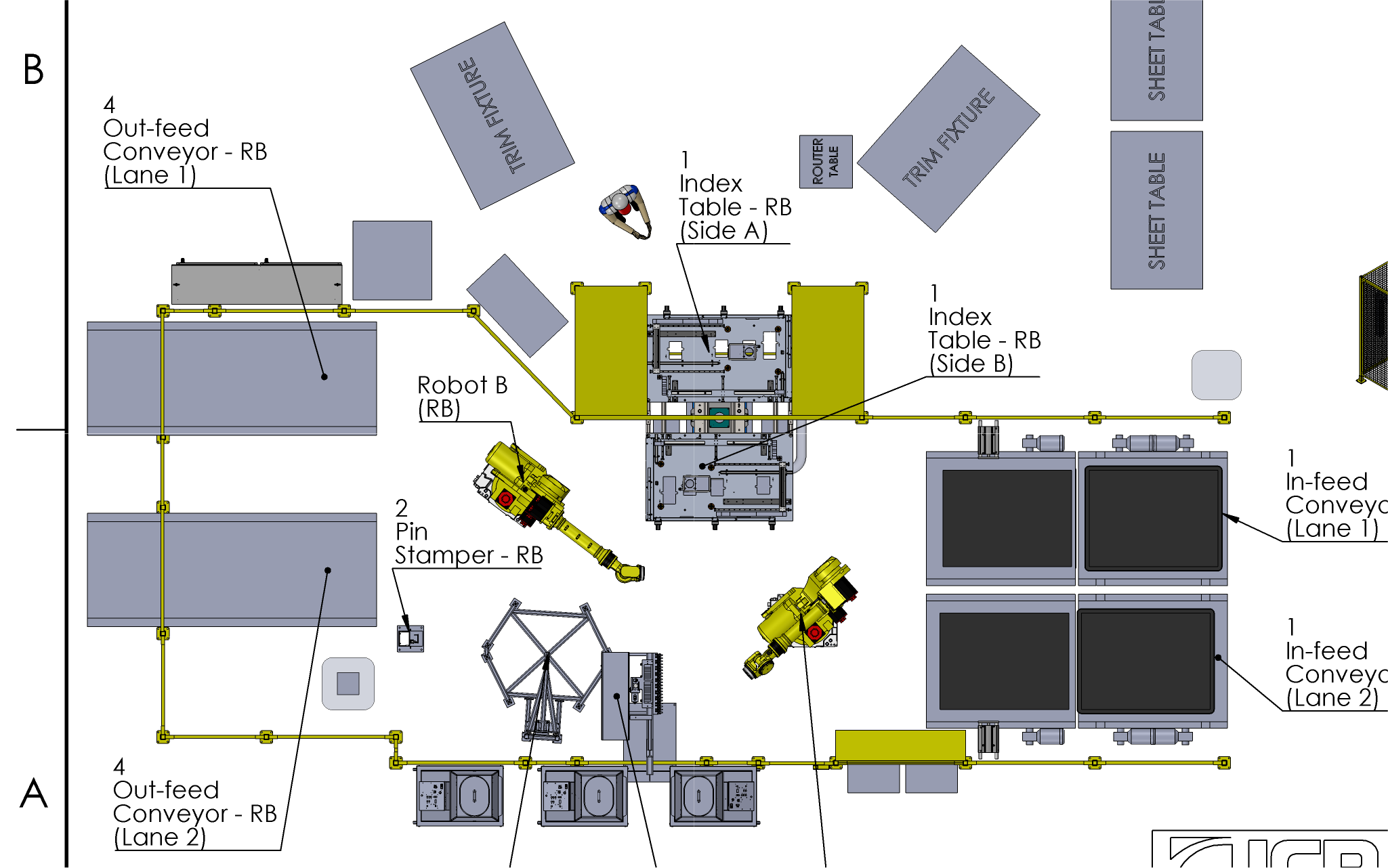

Full Simulation Video

Visually see the paths and movements of the proposed cell along with step-by-step operations and estimated cycle time. Drawings will be provided in either 2D or 3D CAD for a true to scale representation.

Make Way for Something New

Maximize your end of life strategy and get rid of the old with Industrial Facility Decommissioning for a quicker installation experience.

Open Line of Communication

You’ll be assigned a project manager early in the process that will be your main point of contact throughout the entire project to help keep things on schedule and within budget.

In-house Certified Machinery Safety Expert

Safety is at the forefront of each design. CMSE® is a globally recognized qualification enabling a 360° approach to machinery safety.

Gain Peace of Mind

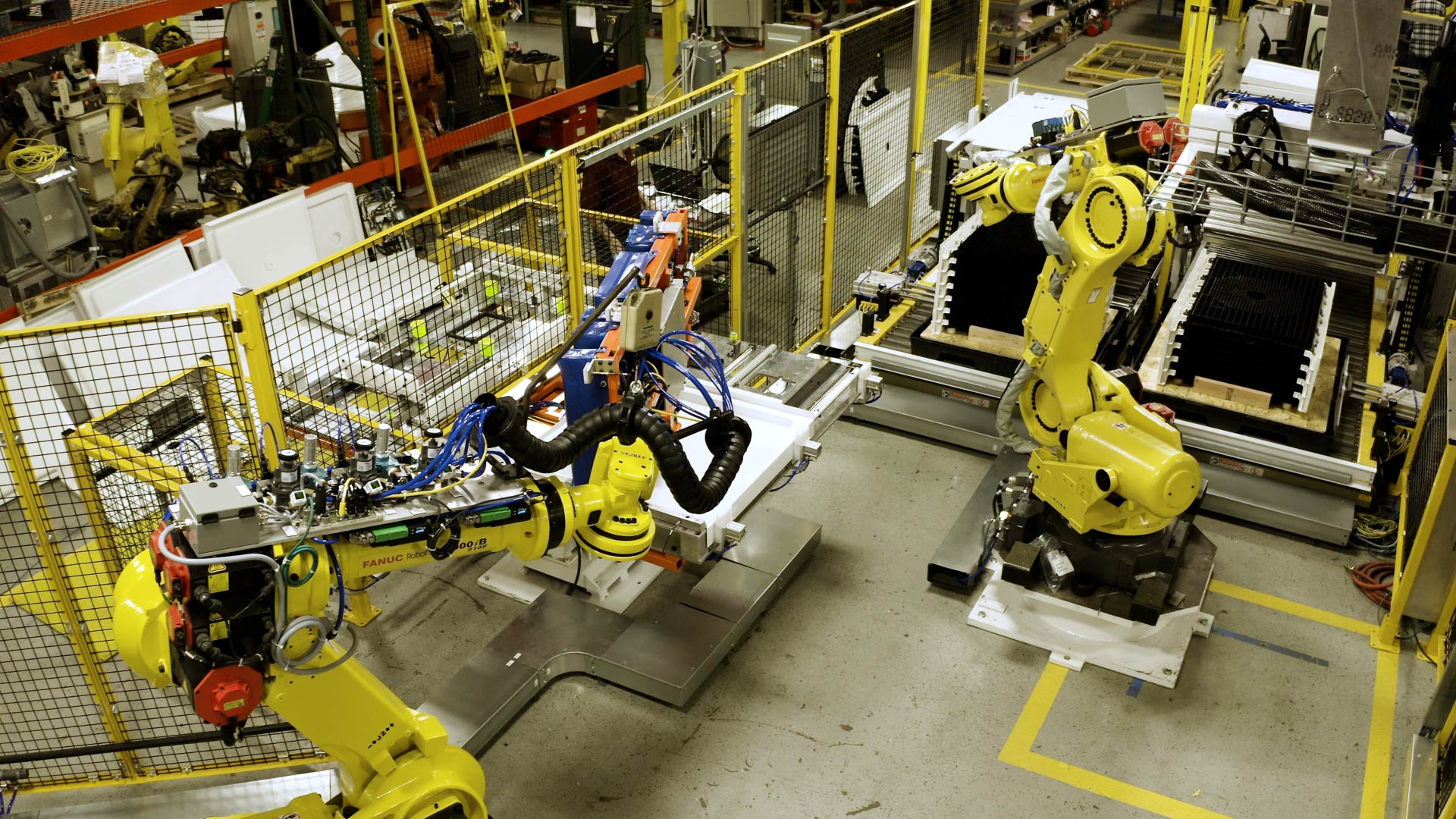

The final run-off takes place at our integration and robotic services facility in Warren, MI. During this time, you’ll have the opportunity to speak personally with the team while we demonstrate the functionality of the entire cell.

Limited systems training is included at no additional cost to learn firsthand from the people who built it. On-site Training Courses using the newly completed cell is available for purchase if a more in-depth experience is required. After your approval, the Field Service team will carefully begin a complete physical installation of your new factory automation system at your facility.

Come See the Integration Process For Yourself

See what our teams are working on and how we’re solving the world’s most pressing manufacturing problems.

Request Facility TourBenefiting From Automation

The reasons to integrate are well documented. Improved safety, ergonomics, and quality drive people towards automation. Use this ROI Calculator for Robotics to show the potentially dramatic impact in cost savings of leveraging a robot versus manual labor over the lifetime of a project. Similar savings and productivity gains can be experienced for non-robot applications. This Pedestal Spot Welding Cell used zero robots and improved throughput by 150%.

Accepting Manufacturing Process and Automation Challenges

We are excited to work with you to increase your company’s productivity, lower costs and raise safety standards. If you’re interested in a custom solution or turnkey robot system, we invite you to fill out the Contact Form.

Consultations are conversational instead of sales focused as together we better define the problem and openly discuss available solutions and any possible alternatives.