Servo Motor Repair Process

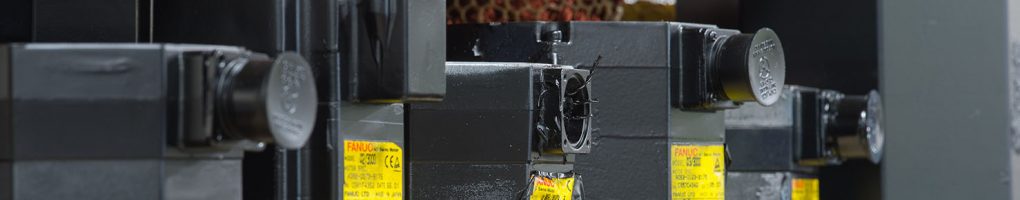

The Servo Motor Repair Process Explained An Exclusive Behind-The-Scenes Look at ICR Service’s Motor Lab in Warren, MI Breaking down the servo motor repair process in 7 easy and straight to the point steps. It’s the next best thing to being there in person although you can do that too. 1. EVALUATION We take data…Read more